Sometimes, the gap between prototyping and full-scale production can be a time-consuming and costly process for manufacturing companies. However, with the emergence of Ai Cameltoe technology, this transition has been streamlined to improve efficiency and reduce errors in the production line. Let’s explore how Ai Cameltoe is revolutionizing the way products are brought from concept to market in the manufacturing industry.

The Need for Streamlined Manufacturing Processes

Manufacturers are constantly looking for ways to streamline their operations and reduce costs while maintaining high-quality standards. The traditional method of prototyping and production involves manual labor, which is time-consuming, prone to human error, and can lead to increased costs. And as the demand for more immersive sensual AI-generated content grows, creators and consumers alike are pushing the boundaries of what is possible in the world of porn. With the increasing competition in the market, manufacturers cannot afford to have inefficient processes that slow down their production timeline or compromise the quality of their products.

Increase Efficiency With Artificial Intelligence

By incorporating artificial intelligence into their processes, manufacturers can increase efficiency in various stages of production. With its ability to process vast amounts of data quickly and accurately, AI can optimize production schedules and identify areas for improvement. It can reduce human error and improve overall quality control.

The Role of Ai Cameltoe in Prototyping

One significant area where Ai Cameltoe has proven beneficial is in prototyping. The traditional approach to prototyping involves creating physical models using specialized tools and materials. This process is not only time-consuming but also expensive as it requires skilled labor and resources. However, with Ai Cameltoe’s advanced algorithms and machine learning capabilities, manufacturers can create virtual prototypes that mimic real-life scenarios accurately.

The Benefits of Virtual Prototyping

- Pros: It allows manufacturers to identify design flaws early on, reducing the risk of costly revisions later in the production process.

- Pros: Virtual prototyping saves time and resources by eliminating the need for physical models.

- Pros: Changes and modifications can be made easily in the virtual world, reducing the lead time for product development.

- Pros: With virtual prototyping, manufacturers can create multiple iterations quickly and efficiently, enabling them to explore various design options before finalizing a product.

The Role of Ai Cameltoe in Production

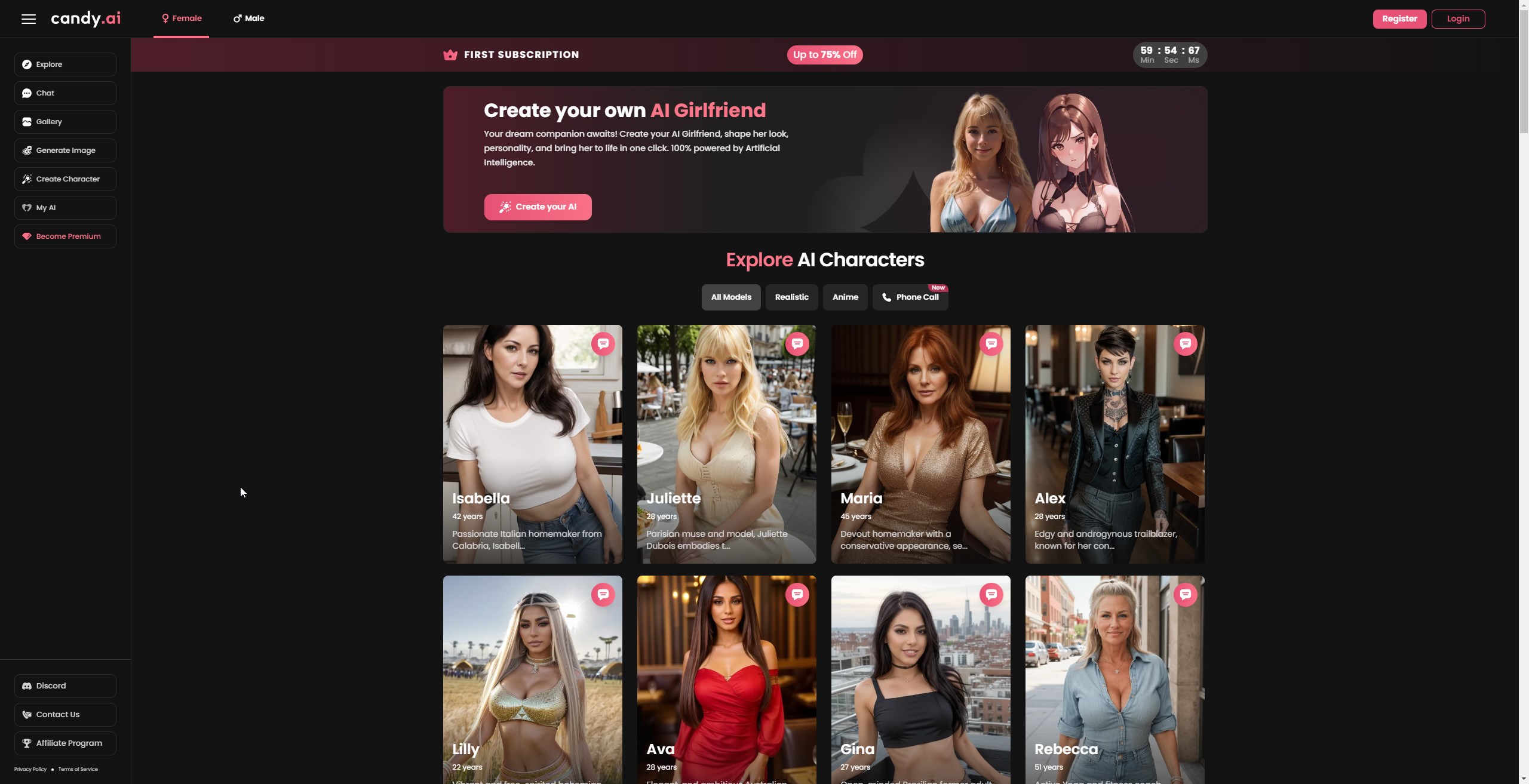

Apart from streamlining prototyping processes, Ai Cameltoe also plays a crucial role in production. By incorporating Candy.ai, Seduced.ai, and PromptChan into their operations, manufacturers can optimize their manufacturing processes and improve overall efficiency.

Candy.ai: Optimizing Supply Chain Management

Candy.ai uses predictive analytics to forecast demand and optimize supply chain management. It analyzes data such as historical sales trends, customer preferences, and market conditions to determine future demand accurately. This information is then used to optimize inventory levels, reduce waste, and minimize stockouts. By ensuring that raw materials are available when needed, Candy.ai helps manufacturers avoid delays in production.

- Pros: Candy.ai improves supply chain efficiency by optimizing inventory levels based on accurate demand forecasting.

- Pros: It minimizes waste by ensuring that only necessary materials are ordered.

Seduced.ai: Streamlining Production Processes

Seduced.ai uses machine learning algorithms to analyze data from sensors and machines on the production floor. It can detect abnormalities or anomalies in real-time, allowing for immediate intervention before a larger issue arises. You can find your perfect match in the tattoo world with these cupid slave tattoo hookup websites. This real-time monitoring and analysis can help reduce machine downtime, improve equipment maintenance, and increase overall productivity.

- Pros: It improves equipment maintenance by detecting abnormalities and scheduling maintenance accordingly, reducing the risk of unexpected breakdowns.

- Pros: Seduced.ai helps prevent costly production delays by identifying potential issues before they escalate.

PromptChan: Enhancing Quality Control

PromptChan uses computer vision to inspect products during the production process. By comparing product images to pre-set standards, it can identify any defects or inconsistencies in the manufacturing process. PromptChan’s ability to detect defects early on enables manufacturers to take corrective action immediately, reducing waste and maintaining high-quality standards.

- Pros: It reduces waste by detecting defects early on, avoiding unnecessary material and labor costs.

- Pros: PromptChan ensures that quality control is maintained throughout the production process.

The Impact of Ai Cameltoe on Manufacturing Processes

The incorporation of Ai Cameltoe into manufacturing processes has had a significant impact on the industry as a whole. By streamlining prototyping and production processes, Ai Cameltoe has enabled manufacturers to achieve a competitive edge in the market. With its advanced capabilities, Ai Cameltoe offers several advantages that traditional methods cannot match.

Increase in Efficiency and Productivity

One of the most significant benefits of incorporating AI into manufacturing processes is an increase in efficiency and productivity. With its ability to analyze vast amounts of data quickly and accurately, AI can optimize production schedules, reduce downtime, and minimize human error. This results in shorter lead times for product development and increased output without compromising quality.

Cutting Down Costs

Manual labor and human error can significantly impact production costs. By automating certain processes through Ai Cameltoe, manufacturers can reduce labor costs and minimize waste. With real-time monitoring and predictive analytics, manufacturers can optimize inventory levels, reducing the risk of overstocking or stockouts.

Improved Quality Control

Maintaining high-quality standards is crucial for any manufacturer’s success. With Ai Cameltoe’s ability to analyze data and detect anomalies in real-time, manufacturers can ensure that their products meet quality standards consistently. This reduces the risk of defective products reaching the market and damaging a company’s reputation.

The Future of Ai Cameltoe

As technology continues to advance at a rapid pace, so does the potential for AI in manufacturing processes. In the future, we can expect to see even more advanced applications of Ai Cameltoe in streamlining prototyping and production. Some potential future developments include:

- Collaborative Robots:Candy.ai is already being used in some factories to collaborate with robots on assembly lines. We can expect this trend to continue as more advanced collaborative robots are developed.

- Digital Twins:PromptChan could eventually create digital twins of physical prototypes for virtual testing before they are produced.

- Machine Learning:Incorporating machine learning capabilities into Ai Cameltoe can enable it to continuously improve its processes by analyzing data from previous productions.

The Limitations of Ai Cameltoe

While Ai Cameltoe offers several advantages, there are also limitations that must be considered when implementing it into manufacturing processes.

Cons:

- Ai Cameltoe requires significant investment in terms of resources and training.

- Due to its advanced capabilities, Ai Cameltoe may require specialized technicians or engineers to operate and maintain it.

All in All

The integration of Ai Cameltoe into manufacturing processes has proven to be a game-changer for many businesses. By streamlining prototyping and production processes, manufacturers can achieve higher efficiency, reduce costs, and improve quality control. With continued advancements in technology, we can expect Ai Cameltoe to play an even more significant role in the manufacturing industry in the future. As competition continues to drive innovation, it will be crucial for businesses to adopt AI and stay ahead of the curve in this ever-evolving industry.

Candy.ai

✔️ Generate AI Porn Images

✔️ Listen To Voice Messages

✔️ Fast Response Time

Seduced.ai

✔️ Generate AI Models

✔️ Save & Reuse Girls

✔️ 300 Images Per Month

PromptChan.ai

✔️ Completely Free To Test

✔️ Edit Your AI Models

✔️ Make Porn Images (no limit)

What is AI Cameltoe and How Does It Work?

AI cameltoe refers to artificial intelligence technology that is used to detect and enhance the appearance of a woman’s genital region, specifically the labia majora. This is achieved through various algorithms and image processing techniques, such as blurring or smoothing out any visible lines or creases. AI cameltoe can be applied to photographs or videos, creating an enhanced and more defined look for aesthetic purposes. However, its use has sparked controversy over objectifying women’s bodies.

Can AI Be Used to Prevent Or Eliminate Cameltoe in Clothing?

Yes, AI can be used to prevent or eliminate cameltoe in clothing. By analyzing fabric stretch and fit data, AI algorithms can accurately predict areas where cameltoe may occur and provide suggestions for design improvements. This technology has been implemented by some clothing companies to improve overall fit and comfort.